Overview machining capabilities

On a company site of 17,000 m², of which 9,500 m² are production area, around 60 million machined parts are produced annually with approx. 100 production machines.

METUSAN TURNING GmbH is specialist in brass turned and milled parts, stamping, pressing, bending and brazing elements and assemblies.

Turning

On conventional (curve/cam control) and computer numerically controlled (CNC) automatic lathes, turned parts made of rod materials (round, tube, squared profiles) are manufactured in any order lot size in a diameter range from 3 to 74 mm (140 mm)

Accuracy requirements of up to +/- 0.02 mm are met by METUSAN in a process-stable manner.

The production of large series takes place on 6- and 8-spindle automatic lathes.

Milling

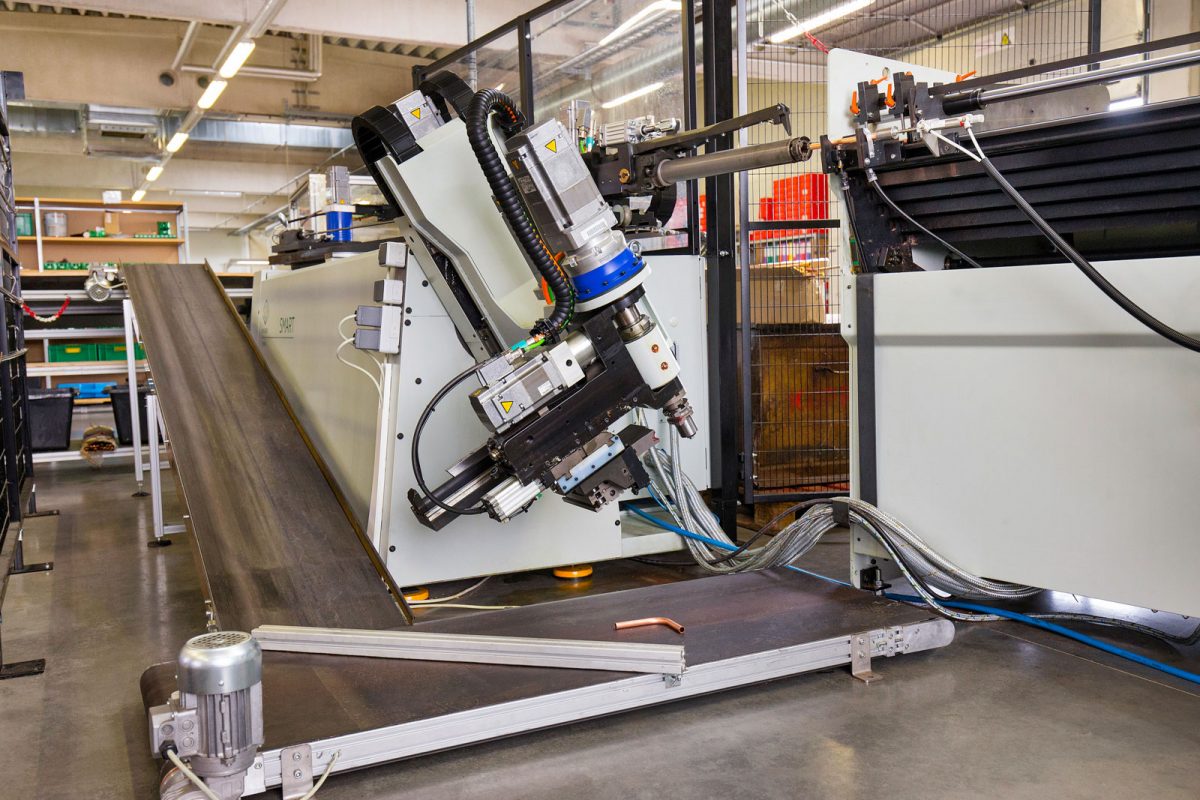

The parts that require very complex multi-axis milling operations are manufactured in machining centers.

The parts are fed by robot control.

Stamping, pressing, bending and brazing

Eccentric, stamping and deep-drawing presses are used to manufacture stamped and drawn parts from sheet metal.

Copper pipes are processed on pipe cutting and pipe bending machines.

In this area there are other production equipments that are used to postprocess turned and milled parts (rotary indexing tables, drilling and milling equipment, flanging machines, etc.).

Assemblies

Depending on the requirements, individual parts are assembled and tested to form a functional assembly group.

Purchased parts such as seals are bought by us or free-issued by our customer.

Contact

METUSAN TURNING GmbH

Wienerfeldstraße 6, 2120 Wolkersdorf

Phone: +43 (0) 2245 3181 0

Fax: +43 (0) 2245 3181 34

office@metusan.at

Parts cleaning

All products are fully automatically cleaned in two ultra-modern cleaning systems, in closed vacuum chambers. Individually adapted cleaning programs guarantee 100% freedom from grease and chips.

Packing & shipping

The parts are assembled, picked, packed and delivered with customer-specific printed labels if required.

Fully automatic high-bay warehouse

Customer-specific parts and standard products are stored in a fully automated high-bay warehouse with 1500 pallet spaces.

Thanks to this large storage capacity, Frame contracts can be produced cost-effectively in one production lot.

Customers order and we deliver promptly.

We offer “just in time delivery” with minimal capital commitment for our customers.