Robot cells support post-processing steps.

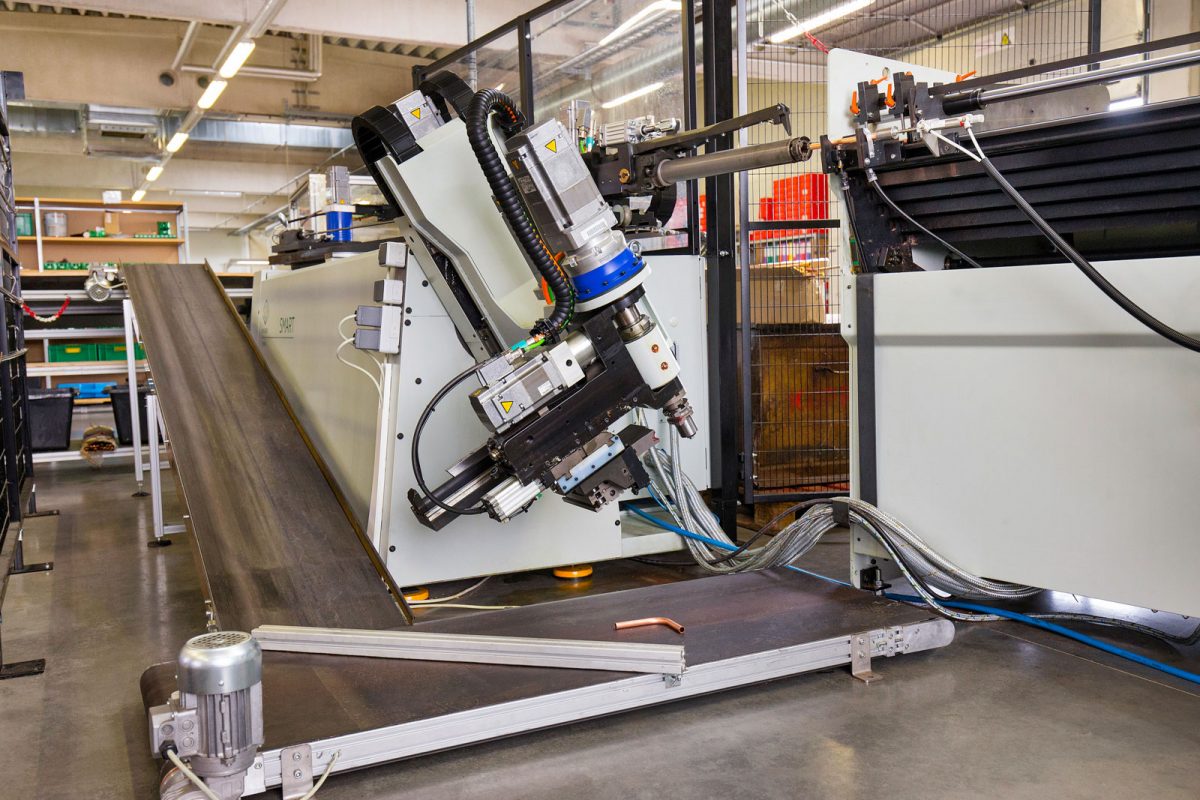

Copper pipes are processed on pipe cutting and bending machines.

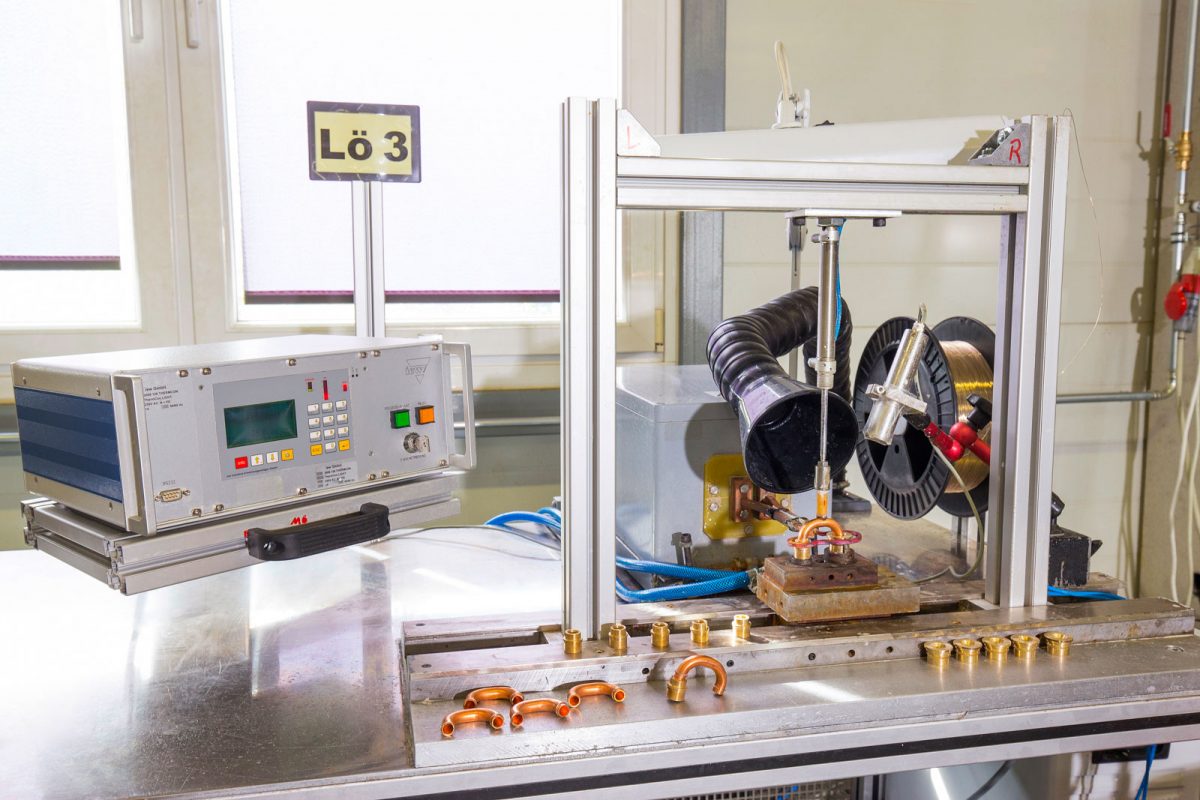

Assemblies can be joined in brazing stations.

METUSAN develops its own production facilities that are used to post-process turned and milled parts (e.g. rotary indexing tables, drilling and milling equipment).

Eccentric, stamping and deep-drawing presses are used to manufacture stamped and drawn parts from sheet metal.

Contact

METUSAN TURNING GmbH

Wienerfeldstraße 6, 2120 Wolkersdorf

Phone: +43 (0) 2245 3181 0

Fax: +43 (0) 2245 3181 34

office@metusan.at

Tube bending machines

CNC tube bending machine BML Smart

8-axis

Max. length: 500 mm

Pipe diameter: min. 6 mm to max. 28 mm

Conventional tube bending machine

Max. length: 1000 mm

Pipe diameter: min 10 mm to max. 22 mm

Hard brazing stations

Brazing stations

Induction process

In-house production of the inductors

Leak test

Post processing machines

Rotary indexing tables with drilling units

Rotary tables with thread cutting units

Clamping ring slitter

Seal drilling device

Pressing, Punching and deep drawing machines

Presses up to 35 tons

Workpiece diameter 200 mm

- Material thickness max. 2 mm